This job consisted of the major modernisation of 3 x 1000kg or 13 persons goods/passenger lifts in a fully functional waste processing plant, the plant was undergoing other renovation works and so maintaining time schedules and completing tasks on time was paramount as site security and Health and Safety protocol was a major factor in our works progression.

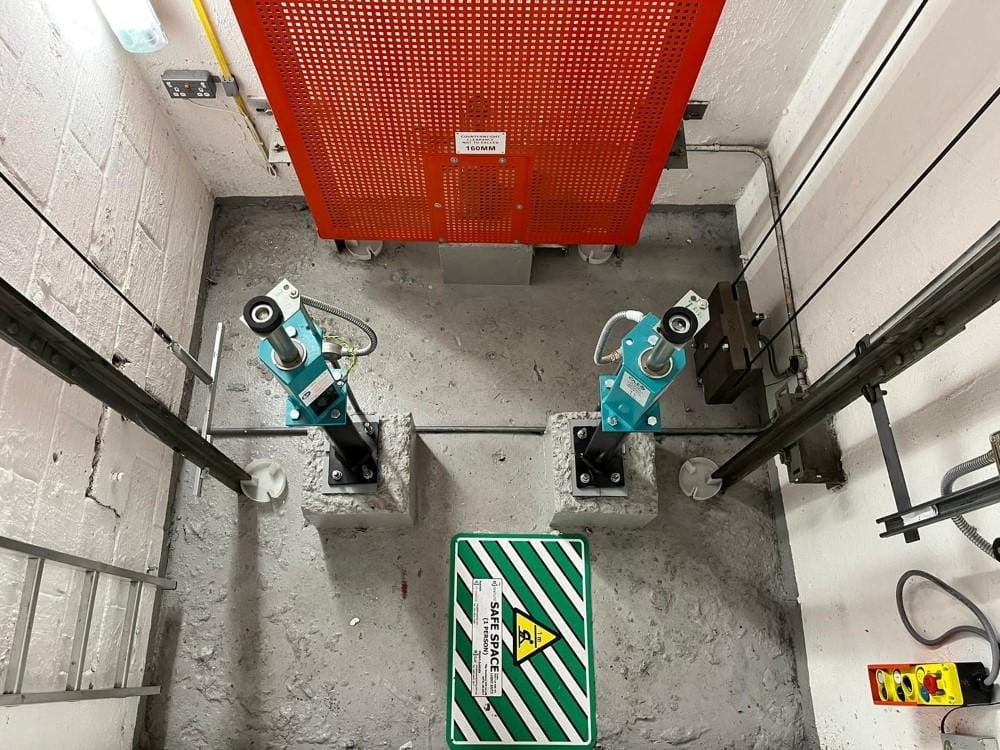

Each of the lifts were open front and rear serving between 5 and 9 floors, the works consisted of stripping down the gear units, removing bearing housings from site for the bearings and seal to be replaced, overhauling the gearbox, replenishing oil and fitting new hoist ropes. Control panels were replaced with state-of-the-art microprocessor panels and rewire of the complete installation. Landing shutter gates were either overhauled or replaced depending on their condition, all landing entrances were fitted with fully compliant VL10 gate locks, lift car picket gates were either overhauled or replaced depending on their condition. The lift cars were relined in aluminium chequer plate, new ceilings & car lighting, new surface mounted hall pushes and digital indicators with a new flush fitting COP fitted with heavy duty US91 push buttons.

We have completed 2 lifts including test and commissioning in the allotted timescale. The client is very pleased with the end product and commended us on our attention to detail in observing site protocol and accuracy in timescale predictions.

LIFT & ESCALATOR MODERNISATION

At VM Elevators we specialise in modernising lift and escalator systems to meet contemporary standards of safety, performance and aesthetics. Our dedicated Operations team of experts assesses existing vertical transportation infrastructure, employing innovative solutions tailored to enhance efficiency and reliability. From upgrading lift control systems to installing energy-efficient components, we ensure seamless integration of modern technologies while minimising disruptions to daily operations. With a focus on sustainability and customer satisfaction, VM Elevators’ modernisation services breathe new lift into aging systems, optimising performance and elevating user experiences.